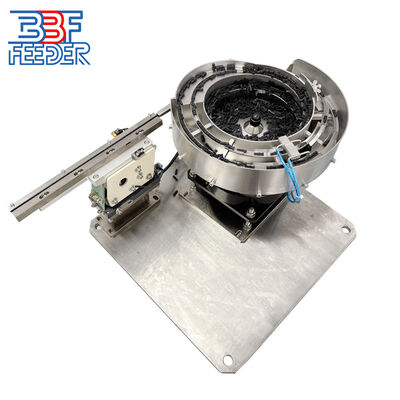

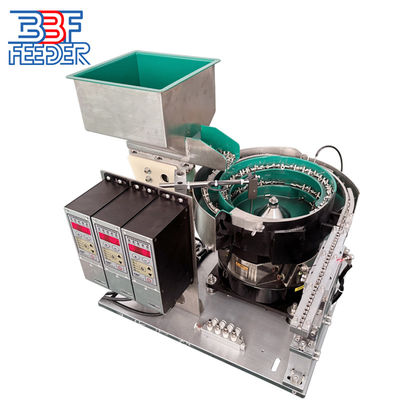

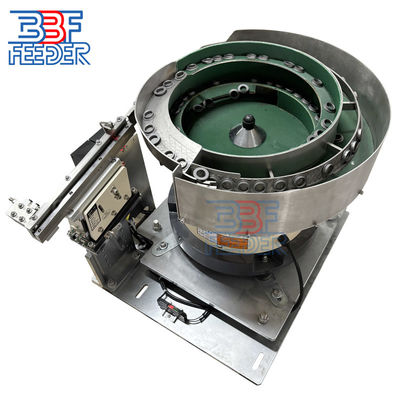

Wholesale Rotary Feeder Noise Reduction Double Bowl Plastic Parts Vibratory Feeder

1 . Descriptions:

Vibratory bowl feeders are widely utilized in industrial production, particularly in industries that require the transportation of large quantities of parts. These sectors include automotive, cosmetics, food, fashion, pharmaceuticals, consumer electronics, electrical components, plastics, and many others.

A key application of vibratory bowl feeders is the conveyance of small bottles and caps. They can transfer these items to the next production stage at a rate of 90 units per minute. For bottled product manufacturing, vibratory bowl feeders are indispensable components of automated production lines. They provide enterprises with a cost-effective automated feeding solution, significantly boosting production efficiency and reducing manufacturing costs.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

Color

|

Green or Based on Customers' Requirement |

| After-sales Service |

Spare Parts and Technology Support |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

3 . Custom Vibratory Bowl Feeders :

A vibratory bowl feeder is an automated feeding device designed for conveying parts, and it is commonly used for transporting gaskets. To ensure the efficient and stable operation of the vibratory bowl feeder, the following points require attention:

1. Selection of Vibratory Bowl Feeder Material

Gaskets are available in various materials, such as rubber, metal, and plastic. Different types of gasket materials require corresponding vibratory bowl feeder materials for conveyance. In general, stainless steel is preferred due to its ease of cleaning, excellent hardness, and wear resistance, making it suitable for conveying gaskets of diverse materials.

2. Outlet Design

The discharge outlet must be precisely designed to ensure that the gaskets can be accurately transported to the predetermined position, guaranteeing seamless integration with subsequent production processes.

3. Monitoring System

A PLC control system and sensors should be installed on the vibratory bowl feeder. These components monitor the gasket conveying status in real time and enable timely adjustments to the feeder’s operation to maintain stability and accuracy.

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!