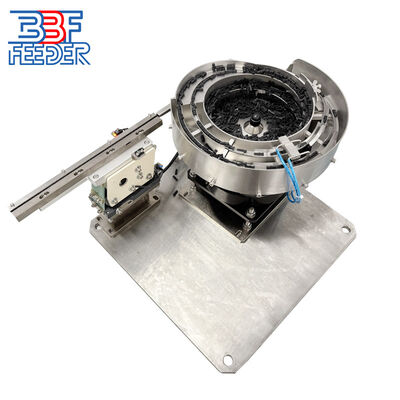

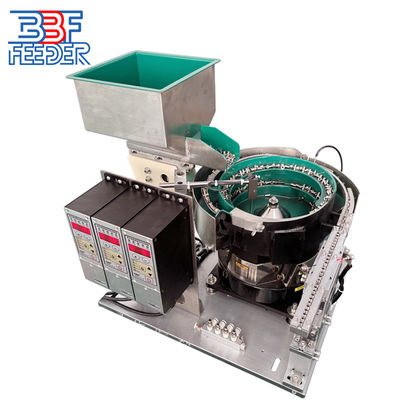

Industrial Vibratory Rotary Bowl Feeder Large Capacity Auto Parts Screws Nuts Feeder

1 . Descriptions:

Vibratory bowl feeders are reliable material conveying systems widely used across diverse industries, including medical manufacturing, food processing, cosmetics, and electronics. Their exceptional performance characteristics significantly enhance productivity in these sectors.

When selecting a vibratory bowl feeder, it is crucial to consider material-specific attributes such as product shape, size, and weight. For conveying materials with high hygiene requirements—such as food and pharmaceuticals—the feeder must be manufactured using food-grade materials or in compliance with medical industry standards to ensure safety and compliance.

To address the unique needs of different customers, vibratory bowl feeders can be equipped with various auxiliary devices. For instance, if customers aim to reduce the frequency of manual loading, a hopper can be added for material storage. This hopper automatically replenishes materials when the feeder runs low, minimizing manual intervention and ensuring continuous operation.

Selecting the right vibratory bowl feeder hinges on both material characteristics and customer-specific requirements. Each feeder we provide is specially customized to meet individual needs. With over 20 years of industry experience, we offer professional design services to help you select or customize the optimal vibratory bowl feeder for your application.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

Color

|

Green or Based on Customers' Requirement |

| After-sales Service |

Spare Parts and Technology Support |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

3 . Custom Vibratory Bowl Feeders for Electronic Components Conveyance :

Vibratory bowl feeders are commonly used for conveying small parts such as electronic components. During the conveyance of electronic components, engineers integrate detection devices into the vibratory bowl feeders to inspect and sort the components, filtering out substandard or damaged products.

Since electronic components are relatively fragile, special attention should be paid to the vibration amplitude and frequency of the feeder during operation. This ensures that the components are not subjected to excessive vibration that could cause damage.

Meanwhile, the surface of the vibratory bowl feeder is coated with specialized materials to reduce friction and electrostatic adsorption of electronic components—two critical factors that could affect component integrity.

After a period of use, the surface of the vibratory bowl feeder needs to be cleaned regularly. Installing dust covers around the feeder can effectively prevent dust accumulation, further protecting the electronic components and maintaining the feeder’s stable performance.

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!