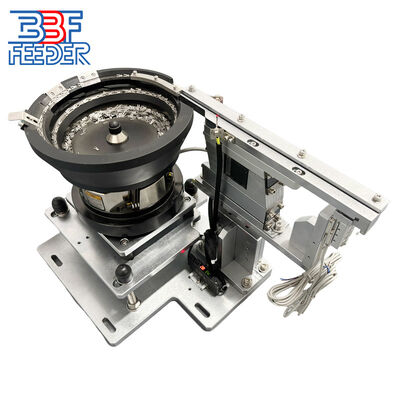

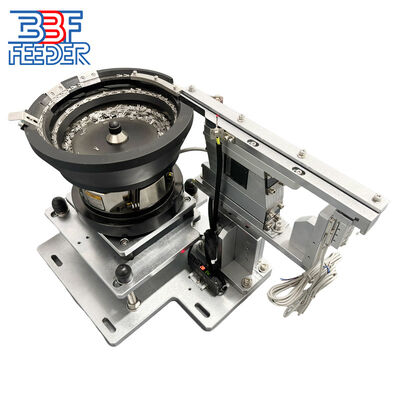

Customized Rotary Vibratory Feeder Metal Parts Small Component Vibrating Bowl Feeder

1 . Descriptions:

In modern manufacturing, automated production has become the preferred choice for most factories. Among the key components of automated systems, vibratory bowl feeders stand out as essential equipment. As an automated material handling solution, they can accurately transport materials to the next stage of the production process.

The adoption of vibratory bowl feeders delivers multiple operational benefits: it significantly boosts production efficiency, reduces manufacturing costs, minimizes human errors, and cuts down on downtime. Repetitive, time-consuming tasks can be efficiently handled by vibratory bowl feeders, further lowering production interruptions.

Vibratory bowl feeders ensure highly precise material conveyance. Equipped with sensors and cameras, they can real-time monitor and analyze the material conveying status, identify defective products, and ensure high-quality products are delivered to consumers. This not only enhances product quality but also strengthens brand credibility and customer loyalty.

With over 20 years of experience in vibratory bowl feeder manufacturing, our company specializes in providing customized solutions tailored to each customer’s unique needs. Our services have been widely acclaimed in the industry. If you have any requirements, please feel free to contact us.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

Color

|

Green or Based on Customers' Requirement |

| After-sales Service |

Spare Parts and Technology Support |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

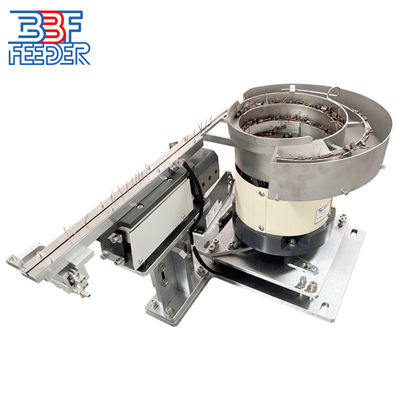

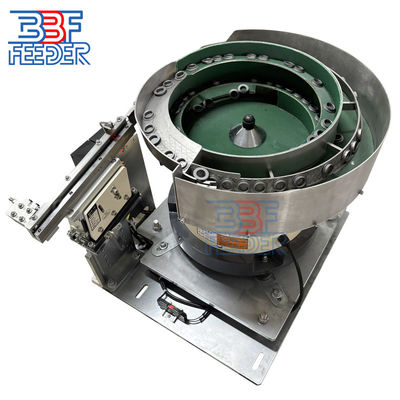

3 . Custom Vibratory Bowl Feeders for Washer Conveyance :

With over 20 years of experience in manufacturing vibratory bowl feeders, we frequently provide customized solutions for customers requiring washer-conveying systems. A vibratory bowl feeder conveying system utilizes the vibratory force generated by the feeder to transport washers along a dedicated track.

Prior to starting the vibratory bowl feeder, manufacturers need to load washers into the feeder. This loading process can be done either manually or via a hopper with a conveyor belt, depending on the production line design and the level of automation.

Once the vibratory bowl feeder is activated by the controller, the bowl produces vibrations that propel the washers onto the track. During transportation, devices such as sensors and guide plates integrated into the conveying system ensure the washers are accurately delivered to the designated location.

Upon reaching the destination, manufacturers can either manually pick up the washers or use a robotic arm to retrieve them for subsequent product assembly.

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!