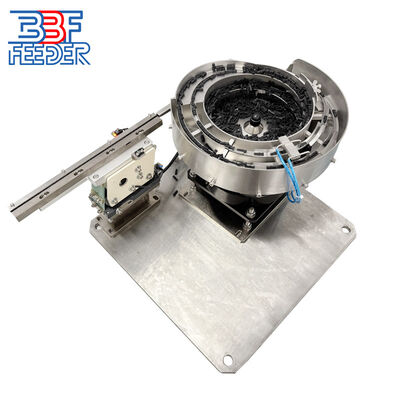

High Performance Vibratory Bowl Feeder Part Orientation Feeder Systems

1 . Descriptions:

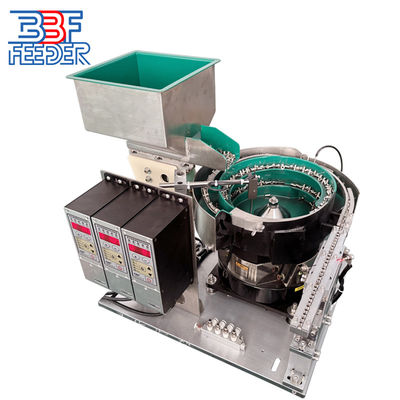

Vibratory bowl feeders are automated feeding devices widely utilized in production lines across various industries. We offer specialized customization services, tailoring vibratory bowl feeders to the unique characteristics of each material to provide a seamless conveying system for your automated production line.

In the electronics manufacturing industry, vibratory bowl feeders play a pivotal role in sorting and arranging electronic components. During the assembly of circuit board fixing parts—where components are often extremely small—manual sorting and assembly are time-consuming and labor-intensive. Replacing manual work with vibratory bowl feeders not only boosts assembly efficiency but also reduces the risk of human error.

In the battery manufacturing industry, ensuring battery safety is paramount. Using vibratory bowl feeders for material conveyance guarantees that battery materials are assembled in the correct orientation. This enhances battery assembly accuracy and ultimately improves overall battery quality.

The advent of vibratory bowl feeders has significantly increased production efficiency, improved product quality, and reduced product damage caused by manual errors. If you require a vibratory bowl feeder, please feel free to contact us. With over 20 years of experience in vibratory bowl feeder production, we are committed to providing you with professional and reliable services.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

Color

|

Green or Based on Customers' Requirement |

| After-sales Service |

Spare Parts and Technology Support |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

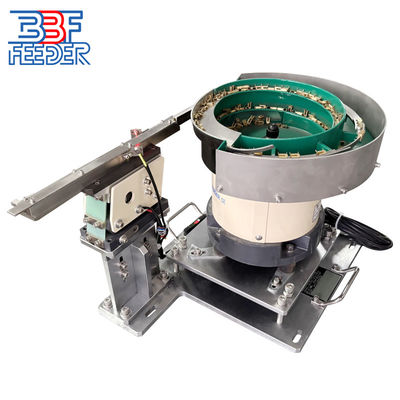

3 . Vibratory Bowl Feeder for American Skincare Bottling Line :

Vibratory bowl feeders are critical equipment in the production of bottled products, responsible for conveying loose plastic bottles sequentially to filling machines for canning.

We previously collaborated with an American skincare product manufacturer. The customer required a conveying speed of 30 bottles per minute to match the throughput of their filling machine. To accommodate an adequate number of plastic bottles, our engineers selected a vibratory bowl feeder with a 900mm diameter. In the track design, baffles and flippers were integrated to ensure all bottles remained in an upright position before being conveyed to the filling machine.

The customized vibratory bowl feeder successfully met the customer’s requirements: it consistently delivered 30 upright bottles per minute, achieving seamless integration with their existing production line.

As a vital component of automated production lines, vibratory bowl feeders significantly boost productivity while reducing labor costs and error rates. If your automated production line requires a tailored vibratory bowl feeder solution, please feel free to contact us.

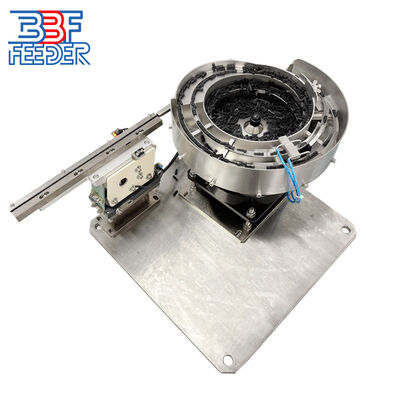

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!