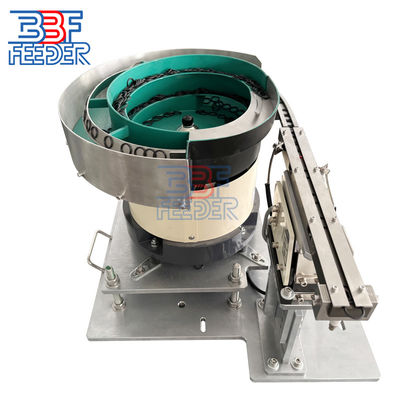

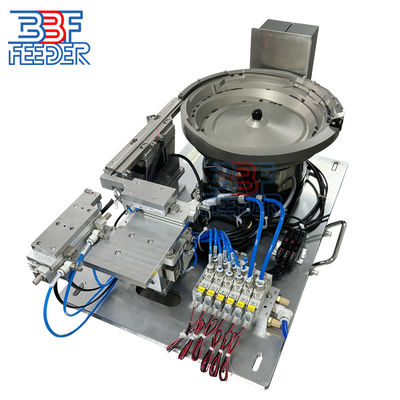

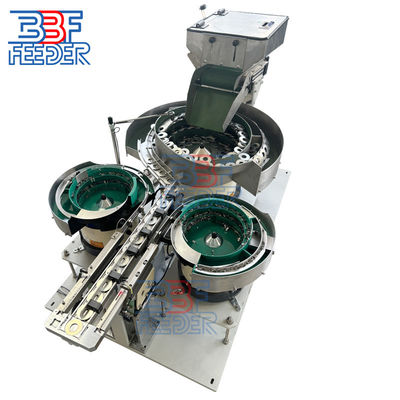

OEM/ODM Vibratory Bowl Feeder Machine Rotary Orienting Metal Screws Feeding System

1 . Descriptions:

In the medical manufacturing industry, numerous products require production in sterile environments—settings that are incompatible with manual operations. As a result, most companies adopt automated production, where vibratory bowl feeders serve as critical equipment for the automated transportation of parts.

When utilizing vibratory bowl feeders in the medical sector, special attention must be paid to material selection. These feeders are typically constructed from stainless steel or FDA-compliant plastics to ensure resistance against corrosion from sterilizers and cleaning agents.

In terms of design, vibratory bowl feeders for medical applications should be engineered for easy disassembly and cleaning. This minimizes the accumulation of bacteria and other contaminants, safeguarding product sterility.

If you require vibratory bowl feeders to build an automated production line, please feel free to contact us. We will provide you with professional, tailored services to meet your specific medical manufacturing needs.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

Color

|

Green or Based on Customers' Requirement |

| After-sales Service |

Spare Parts and Technology Support |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

3 . Conveying Springs with Vibratory Bowl Feeders :

Unlike other components that are not easily deformable, vibratory bowl feeders require special consideration of the unique characteristics of springs when conveying them.

Springs vary in size and shape, which may result in uneven alignment during conveying or even clogging of the conveying pipes or tracks. To address this issue, parameters such as the amplitude, frequency, and angle of the vibratory bowl feeder are adjusted. This adjustment alters the force exerted by the feeder on the springs and optimizes the conveying effect, enabling it to accommodate springs of different shapes and sizes.

Due to their elasticity, springs may deform, collide, or entangle with each other during transportation. To solve this problem, engineers not only optimize the design of the conveying pipes or tracks but also adopt auxiliary devices such as separators. These measures reduce mutual interference and clogging between springs, ensuring the stability and accuracy of the vibratory bowl feeder.

To prevent the springs from being conveyed too fast or too slow, automation equipment such as sensors and PLC control systems are usually installed on the vibratory bowl feeder. These devices monitor and regulate the conveying process in real time, maintaining optimal conveying speed.

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!