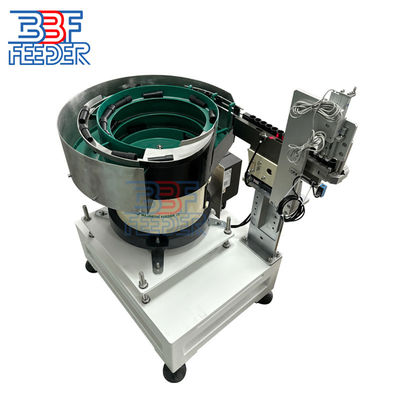

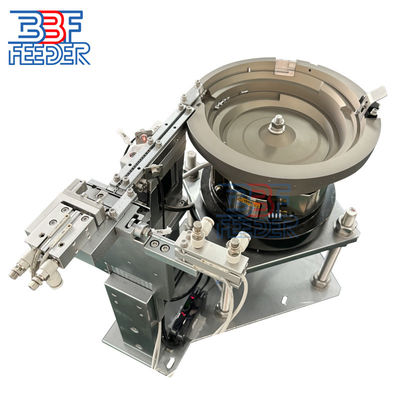

OEM/ODM Assembly Machine Rotary Parts Vibratory Bowl Feeder Design

1 . Custom Vibratory Bowl Feeders :

Vibratory bowl feeders are reliable material conveying systems, widely used in industries like medical manufacturing, food, cosmetics, and electronics. Their excellent features significantly boost productivity for businesses in these fields.

The key is to consider your material’s characteristics—including the product’s shape, size, and weight. For example, if you’re conveying materials with high standards (like food or pharmaceuticals), you’ll need a vibratory bowl feeder made to food-grade standards or medical industry requirements.

We can equip the vibratory bowl feeder with different devices to meet specific demands. For instance, if you want to reduce how often you load materials, we can add a bin for material storage. This bin will automatically refill the feeder when it’s low, cutting down on manual work.

In short, picking the right vibratory bowl feeder depends on your material’s traits and your actual needs—and every feeder we offer is specially customized. With over 20 years of experience, we provide professional design services to help you get the perfect vibratory bowl feeder.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

Color

|

Green or Based on Customers' Requirement |

| After-sales Service |

Spare Parts and Technology Support |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

3 . Vibratory Bowl Feeding for Bottles :

We partnered with an American company that makes skincare products. Their core requirement? The feeder needed to convey 30 bottles per minute, matching the speed of their filling machine.

To meet this need, our engineers made two key design choices:

Bowl size: A vibratory bowl with a 900mm diameter was selected to hold enough plastic bottles for steady feeding.

Track optimization: Baffles and flippers were added to the track. These parts ensure every bottle stays face-up before it’s sent to the filling machine.

The final feeder fully met the customer’s demands—it consistently delivered 30 face-up bottles per minute, syncing perfectly with their production line.

For automated production lines, vibratory bowl feeders are a game-changer: they boost productivity significantly, cut labor costs, and lower error rates. If your automated line needs a vibratory bowl feeder, feel free to contact us.

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!