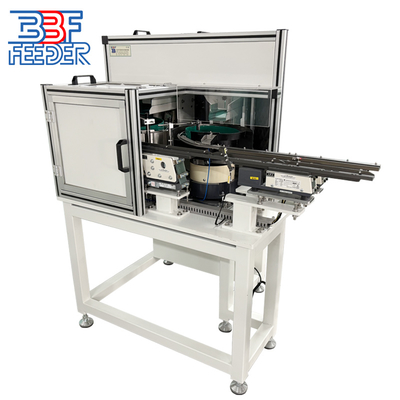

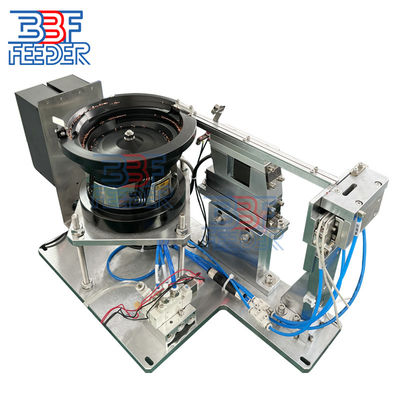

Bespoke Vibratory Bowl Feeder Adjustable Speed Customized Rotary Feeder

1 . Custom Vibratory Bowl Feeders :

In modern manufacturing, automated production has become the go-to choice for most factories—and the vibratory bowl feeder is a vital part of this automation. As an automated material handling system, it can accurately transport materials to the next step in the production process.

Using a vibratory bowl feeder brings clear benefits: it boosts production efficiency, cuts production costs, reduces human error, and minimizes downtime. Repetitive, time-consuming tasks can be handed over to the feeder, which helps keep production running without unnecessary pauses.

What’s more, it conveys materials with high precision. Equipped with sensors and cameras, it can monitor and analyze the material conveyance process in real time, spot defective products, and ensure consumers get high-quality goods. This not only improves product quality but also builds brand trust and enhances customer preference.

Our company has over 20 years of experience in manufacturing vibratory bowl feeders. We offer customized services for every customer and have earned wide recognition in the industry. If you have any needs, feel free to contact us.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

Color

|

Green or Based on Customers' Requirement |

| After-sales Service |

Spare Parts and Technology Support |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

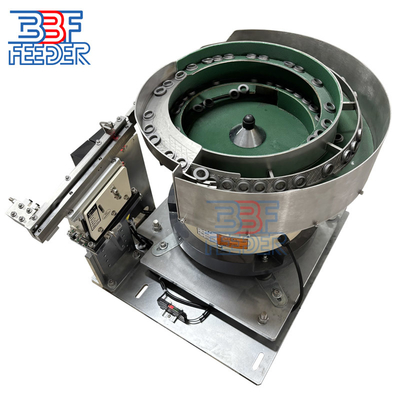

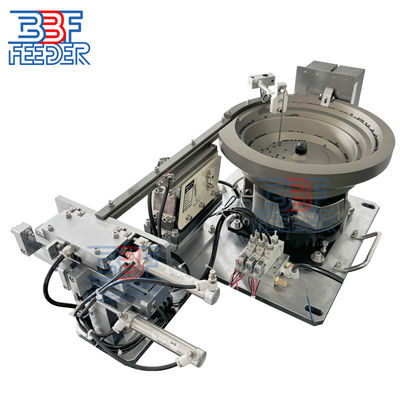

3 . Vibratory Bowl Feeding for Bottles :

We worked with a German company that produces oral liquid, which needed a custom vibratory bowl feeder to convey glass bottles of oral liquid.

Key Design Considerations for Fragile Glass Bottles

Since glass bottles are easy to break, our engineers focused on minimizing bottle collisions and damage:

Anti-collision protection: Rubber cushions were installed at key positions of the vibratory bowl feeder to reduce impact between bottles.

Precise parameter adjustment: Based on the specific size and weight of the glass bottles, we fine-tuned the feeder’s frequency and amplitude—ensuring the amplitude wasn’t too large (which would cause breakage).

Post-Installation: Monitoring & Maintenance

To keep the system running smoothly:

Real-time anomaly detection: The feeder was equipped with sensors and cameras, letting staff spot issues in the conveying process quickly. Usually, simple debugging is enough to restore normal operation.

Routine maintenance: It’s important to regularly check the feeder’s components, clean dust from the bowl and track, and keep the equipment free of debris.

With this custom vibratory bowl feeder, the customer saw significant benefits: labor costs were greatly reduced, the glass bottle loss rate dropped, and overall production efficiency improved.

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!