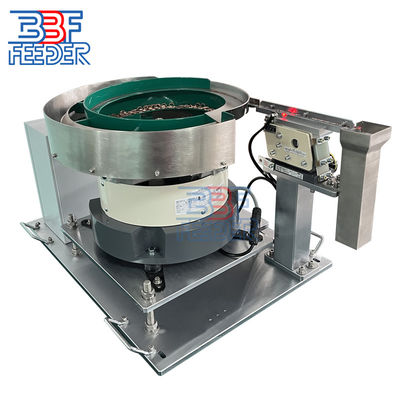

Rotary Vibratory Bowl Feeder Durable Automation Plastic Parts Feeder

1 . Custom Vibratory Bowl Feeders for Industry Needs :

Vibratory bowl feeders are widely used automated feeding devices in production lines across various industries. We offer specialized customization services—tailoring each vibratory bowl feeder to your specific material needs, so it integrates seamlessly into your automated production line’s conveyor system.

In electronics manufacturing, vibratory bowl feeders are key for sorting and arranging electronic components. When assembling fixed parts for circuit boards, these components are often extremely small—manual sorting and assembly is time-consuming and labor-intensive. Replacing manual work with a vibratory bowl feeder not only speeds up assembly but also cuts down on human error.

Safety is critical in battery manufacturing. Using a vibratory bowl feeder to convey materials ensures battery components are assembled in the correct orientation. This boosts assembly accuracy, directly improving the overall quality of the batteries.

The rise of vibratory bowl feeders has significantly increased production efficiency, enhanced product quality, and reduced product damage caused by manual mistakes. If you need a vibratory bowl feeder, feel free to contact us. With over 20 years of experience in manufacturing these feeders, we’re ready to provide you with professional service.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

Color

|

Green or Based on Customers' Requirement |

| After-sales Service |

Spare Parts and Technology Support |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

3 . Vibratory Bowl Feeding for Nuts :

Vibratory bowl feeders are auxiliary feeding equipment for automatic assembly or processing machines. They arrange all kinds of products in order—then work with automatic assembly equipment to build complete products, or pair with automatic processing machinery to finish workpiece processing. A typical use case is in the automobile manufacturing industry, where they’re often used to convey bolts. On auto assembly lines, manufacturers need to send bolts of different shapes and sizes to specific locations, which are then used to fix car parts like the chassis and engine.

Here’s how it works for nut conveying:

The surface of the vibratory bowl feeder has an inclined track. When the vibratory table starts, nuts move forward along this track and end up being conveyed to a preset position. During production, workers first put nuts into the feeder’s material storage area. Once the feeder is activated, it delivers the nuts to the designated location—after that, workers or robotic arms finally install the nuts onto the car.

Using a vibratory bowl feeder to convey nuts not only significantly boosts production efficiency and cuts labor costs, but also avoids errors and improves assembly accuracy. If you have needs in this area, you can consult us—our engineers will customize a vibratory bowl conveying system for you.

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!