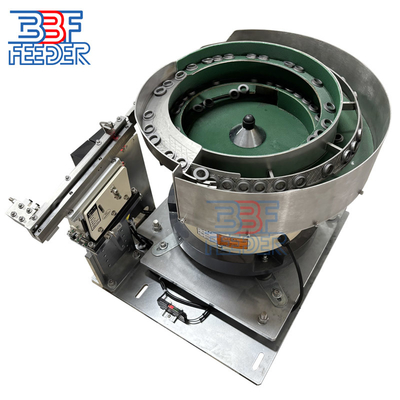

CE Approved Vibration Bowl Feeder Rotary Parts Automatic Feeder Machine

1 . Troubleshooting & Maintenance for Vibratory Bowl Feeders:

When using a vibratory bowl feeder, you might run into some issues. Understanding the causes of these problems helps you fix them quickly.

1. If the feeder can’t run for a long time

This is likely a controller issue. It’s a good idea to keep a spare controller on hand—so you can replace it right away if something goes wrong.

2. If the feeding speed slows down

Common causes include spring cracks, rust, or welding cracks. Here’s how to check and fix:

Spring cracks: Most spring cracks are too small to see with your eyes. Take the spring off the feeder and throw it hard onto a concrete floor. If it breaks, the spring is faulty and needs replacing.

Rust: Check parts that tend to rust. Remove the rust and apply a rust-inhibiting lubricant. For long-term rust prevention, using a stainless steel vibratory bowl feeder works well.

Welding cracks: Carefully check the feeder’s welded areas—especially the discharge port. If you find cracks, re-weld those spots.

To keep the vibratory bowl feeder working normally, regular inspection and maintenance are a must—this prevents disruptions to your production line. We offer a 2-year warranty; if you have any problems, feel free to contact us, and we’ll help resolve them.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

Color

|

Green or Based on Customers' Requirement |

| After-sales Service |

Spare Parts and Technology Support |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

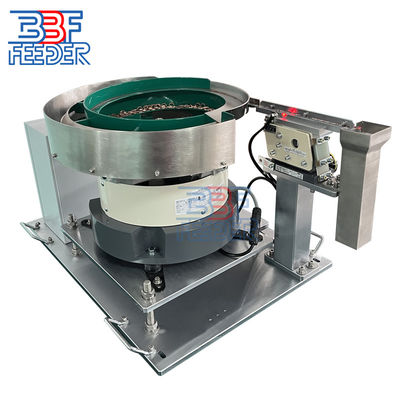

3 . Vibratory Bowl Feeding for Springs :

Unlike other rigid, non-deformable parts, feeding springs with a vibratory bowl requires special consideration of the springs’ unique characteristics.

1. Dealing with uneven size and shape

Springs vary in size and shape, which can lead to uneven arrangement during feeding—even blockages in the conveyor pipe or track. To fix this, you can adjust the vibratory bowl’s parameters (like amplitude, frequency, and angle). These tweaks change how the bowl exerts force on the springs and improves transfer efficiency, helping it adapt to springs of different shapes and sizes.

2. Preventing deformation and interference

Springs are elastic, so they may deform, collide, or get tangled with each other while being conveyed. To solve this, engineers optimize the conveyor pipe or track design. They also add auxiliary devices like separators—these reduce mutual interference between springs and prevent blockages, ensuring the vibratory bowl runs stably and accurately.

3. Controlling feeding speed

To avoid springs being fed too fast or too slow, we usually install automated equipment on the vibratory bowl, such as sensors and PLC control systems. These tools monitor the feeding process in real time and adjust it as needed.

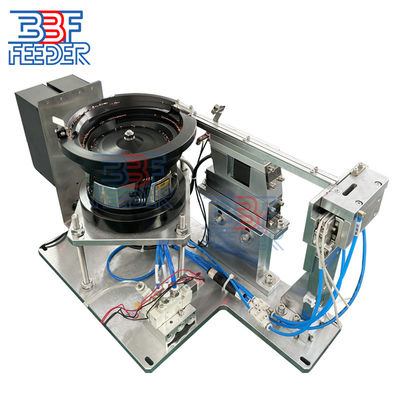

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!