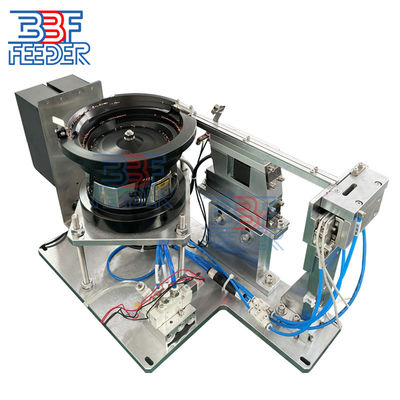

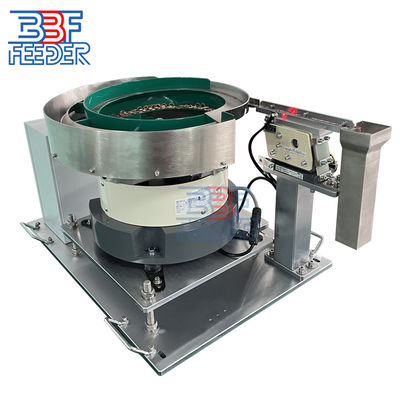

High Speed O Rings Vibratory Bowl Feeder Energy Efficient Silent Operation Feeder

1 . Descriptions:

In the use of vibratory bowl feeder, there may be some problems, the correct understanding of the causes of these problems can be timely solution to these problems.

If there is a vibratory bowl feeder can not run for a long time, it may be a problem with the controller, it is best to prepare a spare controller, problems in time to replace.

If the feeding speed of the vibratory bowl feeder decreases, it may be due to spring cracks, rust, welding cracks and other reasons. Usually cracks in springs are so small that they are invisible to the naked eye. Remove the spring from the vibratory bowl feeder and throw it hard onto the concrete floor. If the spring breaks, there is a problem with the spring. Inspect the parts that agree to rust, remove the rust and use a rust inhibiting lubricant. In order to avoid rust, using stainless steel to make the vibratory bowl feeder can effectively solve this problem. Carefully check whether there are cracks in the welding place of the vibratory bowl feeder, especially the discharge port, and re-weld if there are cracks.

The normal use of the vibratory bowl feeder requires regular inspection and maintenance to prevent affecting the normal production of the production line. We provide two years warranty service, if you have any problems you can contact us, we will solve for you.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

Color

|

Green or Based on Customers' Requirement |

| After-sales Service |

Spare Parts and Technology Support |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

3 . Application of Vibratory Bowl Feeders :

Unlike other components that do not deform easily, vibratory bowl feeders need to take into account the special nature of springs when conveying them.

The size and shape of the springs are not uniform, which may lead to uneven alignment between the springs during conveying or even clogging of the conveying pipe or track. In this case, different shapes and sizes of springs are accommodated by adjusting parameters such as the amplitude, frequency and angle of the vibratory bowl feeder to change the force of the vibratory bowl feeder on the springs and the conveying effect.

Since springs are elastic, they may deform and collide or intersect with each other during transportation. To solve this problem, engineers optimize the conveying pipe or track, and also use auxiliary devices such as dividers to reduce mutual interference and blockage between springs and ensure the stability and accuracy of the vibration plate.

To avoid conveying springs too fast or too slow, we usually assemble sensors, PLC control systems and other automation equipment on the vibratory bowl feeder to monitor and regulate the conveying process in real time.

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!