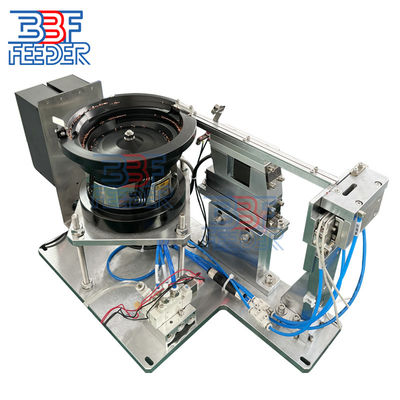

Against Abrasion Vibrating Disk Customized Metal Parts Vibratory Bowl Feeder

1 . Descriptions:

Vibratory bowl feeder is a highly efficient machine for conveying materials, which consists of the following components:

Hopper: The hopper can store materials and add them in time when there is a lack of materials on the vibratory bowl feeder, minimizing manual operation and ensuring the continuous operation of the vibratory bowl feeder.

Bowl: As the core component of the vibratory bowl feeder, engineers will design a special track in the bowl according to the parameters of the material to ensure that the material is transported smoothly in accordance with the state required by the customer.

Driver: The driver is the part of the vibratory bowl feeder that makes the vibratory bowl feeder vibrate, and it utilizes electromagnetism to generate vibration.

Vibratory bowl feeder is an important part of automated production, it can continuously and stably output materials in order, reduce the probability of human error and greatly improve production efficiency. If you have the need, welcome to contact us, we will provide you with professional services.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

Material Speciality

|

Excellent Processing Properties,High Strength, High Hardness |

| Speed |

Based on Customers Requirements |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

3 . Vibratory Bowl Feeder Conveying Needles :

A medical device manufacturer needed to automate the loading of disposable needles, and because the needles are small and sharp, manual operation is prone to errors and lead to danger, so the company approached us to use vibratory bowl feeders to convey the needles.

When conveying medical equipment products should pay close attention to the material of the vibratory bowl feeder, using stainless steel or food-grade plastic to make the vibratory bowl feeder, to prevent contamination of the needle. Sensors and cameras should be installed on the conveying track of the vibratory bowl feeder to monitor the arrangement and conveying of needles in real time, and solve problems in time. The company wanted to reduce the number of manual arrivals, so it added a silo to the vibratory bowl feeder, which can load more needles to ensure that the vibratory bowl feeder continues to run.

The application of vibratory bowl feeder greatly improves the production efficiency and reduces the safety hazard. If your company needs automated production, welcome to contact us, we will provide you with professional services.

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!