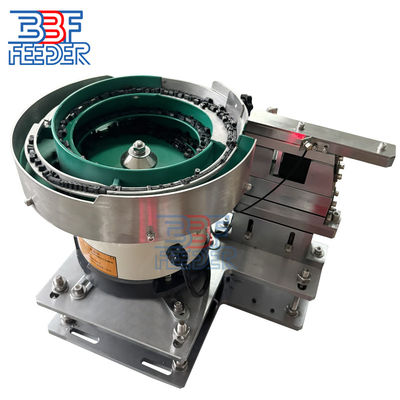

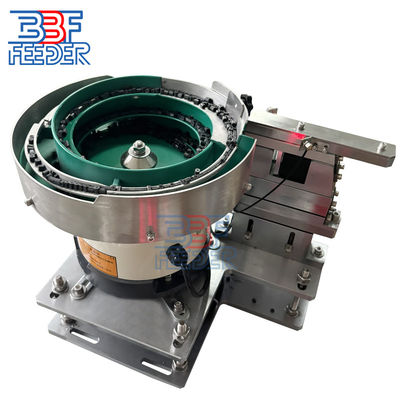

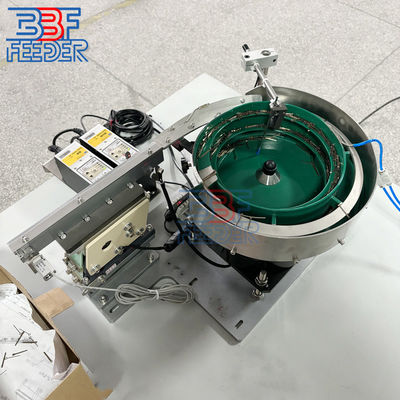

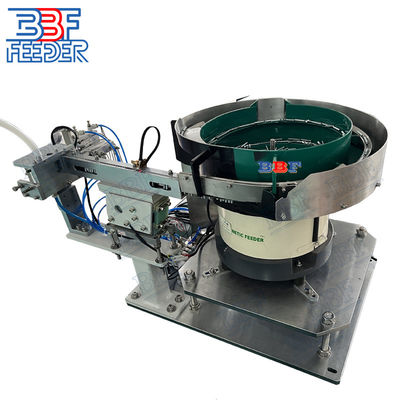

Rotating Feeding Vibratory Bowl Feeder Plastic Parts Feeder Machine

1 . Descriptions:

The vibratory bowl feeder is a critical component of manufacturing automation, as it aligns small parts and components and feeds them into a production line for packaging or further processing. By efficiently sorting and orienting bulk parts, the vibratory bowl feeder surpasses the speed and accuracy of a line operator, resulting in reduced labor costs and increased precision.

Comprising a self-contained system, the vibratory bowl feeder includes a specially tooled bowl that orients components on a vibrating drive unit. The bowl is mounted on a spring-loaded base, with springs designed to control the vertical movement of the bowl when activated. As the components and parts move along an inclined track, they reach the edge of the bowl. The orientation of the bowl's tooling ensures that the components are positioned correctly for processing. In the event of misalignment, the parts are pushed to the center of the bowl, where they cycle through and travel up the track again to be properly oriented.

Overall, the vibratory bowl feeder remains a reliable solution for handling and sorting bulk products in preparation for processing and packaging lines. Its inclusion in manufacturing automation significantly enhances production line efficiency.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

Color

|

Green or Based on Customers' Requirement |

| Speed |

Based on Customers Requirements |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

3 . Vibratory Bowl Feeder Application Examples :

Vibratory bowl feeders are widely used in various industrial sectors that require flexible feeding systems for high-volume production of parts or pieces. They find applications in industries such as pharmaceuticals, consumer electronics, electrical parts, plastics, cosmetics, food, fashion, automotive, and more.

One notable application of vibratory bowl feeders is in vial and tube capping machines. These automated systems are designed to handle small polypropylene screw-on caps for microcentrifuge tubes and vials. The caps and vials are fed from vibratory bowls, with a feeding rate of approximately 80 parts per minute. The system can be easily adjusted to accommodate similar products.

Another application of bowl feeders is in pill bottling systems. Large batches of pills or capsules are dispensed into the vibratory bowl feeder for counting and bottling. The vibratory feeder's vibration ensures that the pills continue moving toward the exit and into the bottle, one by one, without congestion.

Vibratory bowl feeders provide industries with a cost-effective automated production system that increases efficiency while reducing production costs. They offer a reliable and efficient solution for parts feeding in various manufacturing processes.

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!