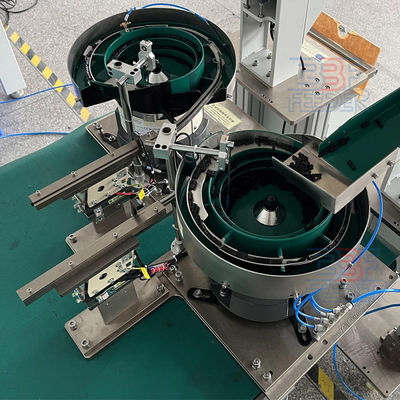

Stainless Steel Vibrating Linear Feeder Low Noise Vibration Bowl Feeder

1 . Descriptions:

The history and significance of bowl feeders in manufacturing and automation can be traced back to the early 20th century. Originally invented by Swedish engineer Erik Erikson, the first vibratory feeder consisted of a metal trough mounted on springs and powered by an eccentric motor. It was primarily used to transport coal and other materials.

In the 1950s and 1960s, vibratory feeder bowls gained popularity in the manufacturing industry for feeding and orienting small parts. The first commercial vibratory feeder bowl emerged in the United States, specifically designed for the automotive industry.

As time passed, vibratory feeder bowl technology continued to improve. In the 1970s and 1980s, electronic controls were incorporated into the bowls, enabling better control over the feeding process. This advancement opened up a wide range of applications across industries such as electronics, pharmaceuticals, food and beverage, and automotive.

Apart from manufacturing and automation, vibratory feeder bowls have found utility in research and development settings. They have been used to study the behavior of small particles and materials due to their versatility and reliability.

Today, bowl feeders serve as accurate and efficient tools for sorting, ordering, and orienting components during the manufacturing or packing process. Positioned at the beginning of a production line, these feeders receive parts from an operator, sort and orient them, and feed them into a linear or nest or an index table for further processing.

Vibratory feeder bowls have become an integral component in numerous manufacturing and automation processes, with their long history of evolution and continuous improvements.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

Material Speciality

|

Excellent Processing Properties,High Strength, High Hardness |

| Speed |

Based on Customers Requirements |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

3 . How to Integrate a vibratory bowl feeder :

To integrate a vibratory bowl feeder effectively, a systematic approach should be followed. Here is a step-by-step guide:

Step 1: Needs Assessment

Begin by thoroughly evaluating your manufacturing process to identify the specific components that would benefit from a bowl feeder.

Step 2: Customization and Tooling

Collaborate with feeder manufacturers to design customized tooling that aligns with the unique requirements of your components.

Step 3: Feeder Configuration and Testing

Configure the bowl feeder to optimize the orientation and feeding process. Conduct rigorous testing to ensure reliable performance before deploying it.

Step 4: Automation Integration

Integrate the bowl feeder seamlessly with your existing automation systems. This involves establishing efficient communication and coordination with downstream equipment.

Step 5: Monitoring and Maintenance

Implement a regular maintenance schedule to monitor tooling wear, promptly address any issues, and prolong the lifespan of the feeder.

Vibratory bowl feeders have become indispensable in the automotive industry, significantly improving efficiency and precision in component assembly. By understanding their applications, addressing integration challenges, and following best practices, manufacturers can fully unlock the potential of these versatile devices. This, in turn, contributes to the seamless production of high-quality vehicles.

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!