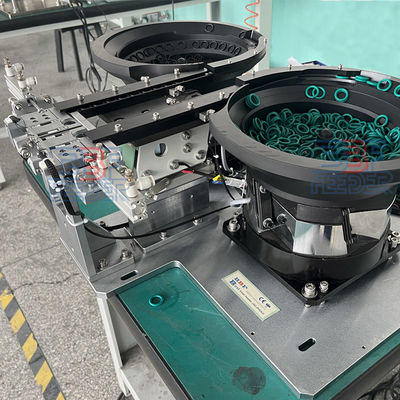

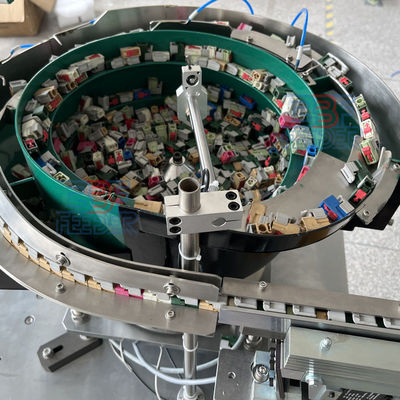

Control Speed Vibrating Bowl Feeder Bottle Lid Caps Automatic Rotary Feeder

1 . Descriptions:

Efficient part handling is crucial in automated assembly and manufacturing, and the Vibratory Bowl Feeder is a versatile tool that plays a vital role in this domain. It reliably orients and feeds parts from bulk, significantly enhancing production efficiency and accuracy when combined with well-designed tooling.

To achieve optimal performance, tooling design cannot follow a one-size-fits-all approach. It necessitates a deep understanding of the parts' characteristics and the specific requirements of the assembly process. Engineers often iterate through prototyping and testing stages to fine-tune the tooling.

Several factors should be considered in tooling development. First, the tooling surfaces must align with the parts' geometry to control and guide their motion. Complex or unique part shapes may require specialized tooling, and 3D profiling can assist in customizing the geometry.

The selection method employed can vary, and the tooling is shaped accordingly. Mechanical tooling and precise air jets are commonly used for selecting many components, while others may require pre-orientation through tooling and final orientation using sensors or vision sensors.

The required feed rate can influence the tooling selection. Higher rates may necessitate multiple selection passes and merging of oriented parts, so attention must be given to the clearance of selection tooling to avoid part jamming in faster running bowls.

Simplicity of design is essential to avoid manufacturing costs. Complex tooling with numerous custom parts can increase expenses, whereas simpler modular tooling is easier to maintain and reconfigure.

The choice of materials for the bowls depends on the installation environment. For example, pharmaceutical applications may require high-grade stainless steels and closer attention to the level of finish compared to industrial applications.

To reduce excess noise and impact, durable linings like polyurethane can be added to dampen the impacts and noise generated during the process.

Specialized coatings, such as titanium nitride, improve wear resistance and prevent galling, leading to a longer service life of the tooling in heavy-duty applications.

By considering these factors and experimenting with different tooling configurations, manufacturers can achieve optimal performance from their vibratory bowl feeding systems. Tooling design is an art that requires experience and testing to master. However, with the right tooling, vibratory bowls become highly flexible and efficient solutions for parts feeding.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

Bowl Finishing

|

Polishing or PU Coating |

| Speed |

Based on Customers Requirements |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

3 . Maintaining and Servicing Vibratory Bowl Feeders:

Vibratory bowl feeders play a vital role in manufacturing, efficiently sorting and feeding components in industries like automotive and electronics. To ensure optimal performance and uptime, regular maintenance is essential.

Operators should conduct routine maintenance on a daily, weekly, and monthly basis, including inspections and cleaning. Qualified technicians should perform more complex preventative maintenance tasks annually.

During the annual service, experienced technicians carefully inspect major components, looking for visible signs of wear, damage, or loose parts like cracks, deformities, or excessive wear on the bowl surface. They also assess the condition of springs, bolts, and other fasteners for fatigue or degradation.

The annual service involves thorough cleaning of components, repair or replacement of worn or damaged elements, upgrading outdated components, and conducting calibrations and test runs to meet OEM specifications. This comprehensive service ensures peak efficiency and minimizes the risk of breakdowns. Technicians may suggest upgrades, repairs, or design improvements, such as replacing worn bowl liners and cradles, relining and resurfacing the bowl, refurbishing or replacing drive coils and mechanisms, and repairing or replacing worn or damaged tooling.

Performing annual service procedures maximizes uptime and minimizes unplanned downtime on the factory floor. The expenses of preventative maintenance are far outweighed by the costs and production impacts of unexpected equipment failures.

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!