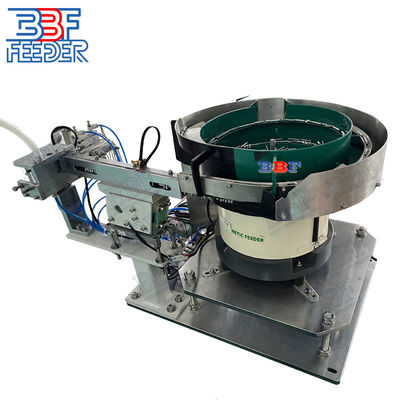

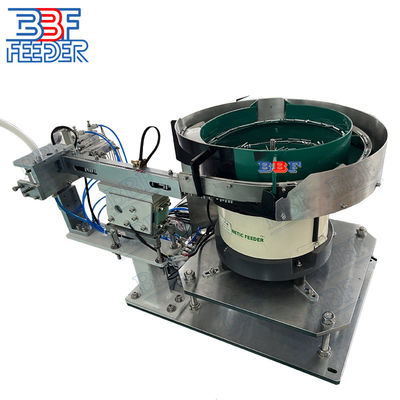

Cost Effective Vibratory Bowl Feeder Screws electromagnetic vibrating feeding machine

1 . Descriptions:

Vibratory bowl feeders are essential components in various industries, providing a reliable and efficient method for sorting and orienting parts. This article explores the key steps and considerations in designing a vibratory bowl feeder.

Step 1: Understanding the Components

Before diving into the design process, it's crucial to understand the basic components of a vibratory bowl feeder:

Bowl: Made of stainless steel, the bowl is where the parts are placed. It has a helical track or multiple tracks that guide and orient the parts.

Drive Unit: The drive unit consists of an electromagnetic coil and a spring system, producing the necessary vibrations to move the parts.

Controller: The controller regulates the frequency and amplitude of the vibrations, providing precise control over the feeding process.

Step 2: Determining Part Characteristics

To design an efficient vibratory bowl feeder, understanding the characteristics of the parts to be fed is crucial. Consider the following aspects:

Size and Shape: Irregularly shaped or sized parts may require special considerations in bowl design for proper orientation.

Material: Different materials have varying friction coefficients and respond differently to vibration, which affects how parts move and orient within the bowl.

Weight: The weight of the parts determines the required strength of vibrations, with heavier parts needing more powerful movement and lighter parts requiring gentler motion.

Step 3: Selecting Bowl Geometry

The bowl's geometry plays a critical role in the design process. Consider the following factors:

Bowl Shape and Size: Choose the right bowl shape and size for optimal performance. The bowl's shape should align with the parts being fed, ensuring smooth and consistent flow. Additionally, consider the bowl's size in relation to the parts' dimensions to avoid inefficient feeding or jams.

Track Configuration: Determine the number and arrangement of tracks within the bowl based on the desired orientation and feeding rate.

Slope Angle: The angle of the bowl's slopes affects the movement of the parts. Steeper slopes may be necessary for faster feeding rates.

Track Width and Depth: Choose dimensions that accommodate the size of the parts while preventing jams or clogs.

Designing a vibratory bowl feeder requires careful consideration of the components, part characteristics, and bowl geometry. By following the key steps outlined in this article, you can ensure the effectiveness and efficiency of the feeder in sorting and orienting parts for further processing or assembly.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

Material Speciality

|

Excellent Processing Properties,High Strength, High Hardness |

| Speed |

Based on Customers Requirements |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

3 . Designing an Efficient Vibratory Bowl Feeder:

Vibratory bowl feeders are crucial components used in various industries for sorting and orienting parts. This article outlines the key steps involved in designing vibratory bowl feeders and highlights important considerations at each stage.

Step 1: Understanding the Components

Grasp the fundamental components: bowl, drive unit, and controller.

The bowl serves as a receptacle with tracks to guide and orient parts.

The drive unit generates vibrations, while the controller regulates frequency and amplitude.

Step 2: Determining Part Characteristics

Consider part size, shape, material, and weight.

Irregular shapes may require special bowl design considerations.

Friction coefficients and part response to vibrations affect movement and alignment.

Step 3: Selecting Bowl Geometry

Choose an optimal bowl shape and size.

Align the bowl with the parts for a smooth and consistent flow.

Determine track configuration, slope angle, and dimensions to prevent jams.

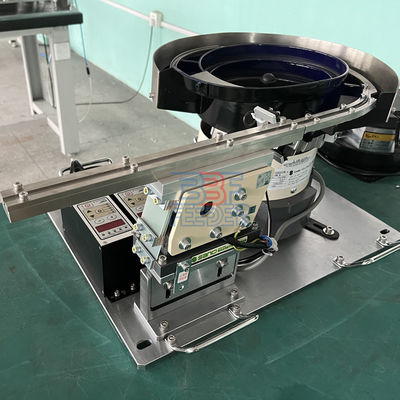

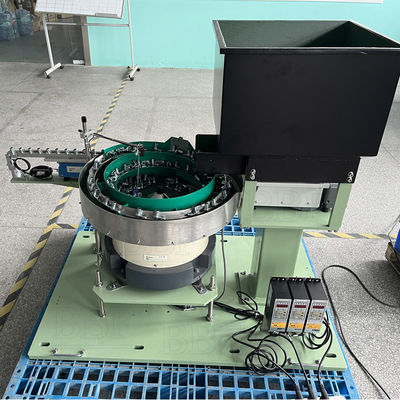

Step 4: Designing the Base Unit

The base unit houses electromagnetic coils and generates vibrations.

Consider drive unit types (half-wave, full-wave, high-speed) based on application requirements.

Choose an appropriate spring system to balance coil force and ensure stable vibration.

Step 5: Implementing Controls

The control system regulates vibration frequency and amplitude.

Ensure variable settings for different parts and feeding requirements.

Consider feedback mechanisms for real-time adjustments.

Step 6: Testing and Optimization

Thoroughly test the feeder's performance against desired specifications.

Fine-tune parameters such as vibration settings and track geometry.

Conduct stress testing to identify potential issues.

Designing a vibratory bowl feeder requires understanding part characteristics, selecting appropriate bowl geometry, designing the base unit, implementing controls, and conducting testing and optimization. By following these steps and ensuring continuous monitoring and maintenance, an efficient and reliable feeder can be created to meet specific application needs.

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!