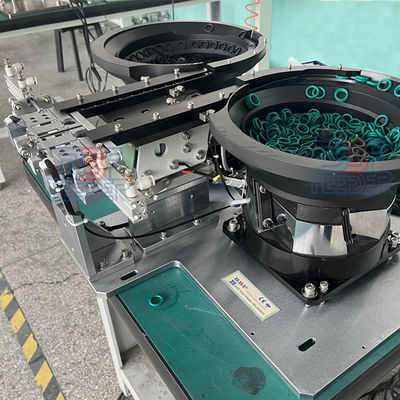

Vibration Discs Vibrating Bowl Feeder Needle Brass Pin Studs Rotary Bowl Feeder

1 . Descriptions:

Electric Vibratory bowl feeders are designed for autonomous operation with minimal human intervention, but regular maintenance is crucial for optimal performance and to prevent malfunctions. Neglecting maintenance can result in various problems such as excessive noise, reduced feed rate, intermittent operation, and the emergence of dead spots in the feeder bowl.

A decline in feed rate often occurs after prolonged use and can be caused by a splintered spring or degradation of the rubber feet. Cracks and holes in the spring can lead to decreased performance, while environmental factors like high temperatures can cause the rubber feet to become soft, swollen, or damaged. Other factors contributing to reduced feeder performance include the absence of a feeder cover, corrosion of spacers and springs, a significant gap between the armature and the coil, and weld seam breakage in the coil assembly.

Regular maintenance is essential to maintain optimal performance. This includes replacing damaged springs, ensuring proper installation on a level surface, inspecting and replacing worn rubber feet, and addressing corrosion or weld seam breakage. By prioritizing maintenance, you can extend the lifespan of your electric vibratory feeder and ensure consistent and efficient operation.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

After-sales Service

|

Spare Parts and Technology Support |

| Speed |

Based on Customers Requirements |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

3 . 4 Tips to Reduce Vibratory Feeder Coil Burnout:

To ensure the optimal functioning of Vibratory bowl feeders and prevent equipment failure, follow these troubleshooting tips:

Check the spring pack: Ensure the load on the bowl does not exceed the manufacturer's specified capacity, preventing spring breakage and equipment failure.

Verify coil functioning: Inspect the coil for gaps or reduced functionality, as they can cause heat generation and issues. Assess the coil's strength and functionality.

Monitor output: Match the voltage and frequency output from the machine and controller to the required specifications. Use the appropriate controller (AC or DC) based on the machine's needs.

Choose the correct input: Select and monitor the input voltage carefully. Using a voltage lower or higher than required can lead to performance issues, overheating, and system breakdown.

By following these steps, you can maintain a smooth operation for your vibratory feeder system. If problems persist or concerns arise, contact your supplier or maintenance service provider for professional assistance. Addressing minor issues promptly can prevent them from escalating into major problems in the future.

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!