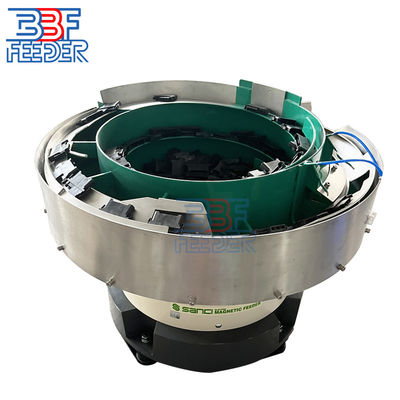

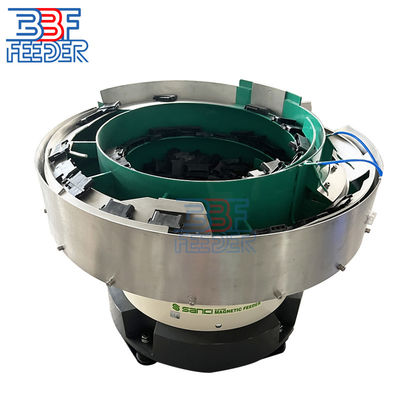

Steady Speed Vibration Bowl Feeder Plastic Socket Sorter Spare Parts Feeder

1 . Descriptions:

Vibratory feeder systems are highly effective in optimizing production processes in the medical products manufacturing sector. These automation machines offer automatic servo control, adjustable vibration angles, and impressive feed rates, making them ideal for feeding items like needles, caps, vials, and sanitized staples on medical/pharmaceutical assembly or packaging lines.

With a variety of specifications available, vibratory feeders can achieve feed rates of up to 1800 parts per minute. This makes them a cost-effective and efficient solution for feeding medical/pharmaceutical parts and products such as syringes, cannulated screws, scalpels and surgical blades, blood collection tubes, and plastic bottles.

Equipped with a variable speed control box, these automation machines provide precise control over the vibration of the bowl feeder. The feed rates can be adjusted to match the yield rate of the assembly line, ensuring optimal performance and productivity.

Medical/pharmaceutical grade vibratory bowl feeder systems are engineered to meet specialized requirements and utilize FDA-approved components. They feature complete stainless steel construction with easily cleanable parts, ensuring durability and the ability to withstand rigorous wash-downs with industrial cleaning solutions. The bowl, welds, and inside tracking are grounded and hand-polished for smoothness and a pit-free design. These systems also employ heavy-duty construction with corrosion-resistant stainless steel fasteners and hardware. The weld seams are filled and grounded, and the bowls are tab-mounted for easy removal. Stainless steel drive unit covers and non-contact parts level sensors are additional features offered.

Vibratory feeders for medical/pharmaceutical applications are available with various coating options, such as powder coating and spray-on coatings, to meet specific requirements and enhance functionality.

Medical/pharmaceutical grade vibratory bowl feeders can be customized to incorporate unique features that fulfill the hygiene requirements of the medical and pharmaceutical industries, ensuring compliance with industry standards.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

After-sales Service

|

Spare Parts and Technology Support |

| Speed |

Based on Customers Requirements |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

3 . Increase the Life of Vibratory Feeder Bowls:

Electric rotary vibrator feeders are robust machines designed to transfer products from small to large hoppers. These feeders exert powerful force throughout the feeding system and are known for their durability, allowing them to withstand harsh operating conditions.

To maximize the lifespan of your electric rotary vibrator feeder, it is crucial to implement the following practices:

Regular Maintenance:

Conducting regular maintenance procedures is essential for optimal performance. Instead of waiting for failures to occur, proactive maintenance should be performed. Regular upkeep significantly increases the longevity of the feeder and its components.

Adherence to Manufacturer Specifications:

Manufacturers provide usage guidelines based on comprehensive performance tests conducted prior to product sale. It is vital to communicate and strictly follow these guidelines. They ensure proper operation and prevent premature wear and tear.

Duty Cycle Limits:

Operating the electric rotary vibrator feeder beyond its specified duty cycle limits can shorten its lifespan. To extend the product's life, it is important to operate within the recommended duty cycle limits. This prevents excessive strain on the feeder's components.

Respect Product Limitations:

Operate the electric rotary vibrator feeder within its physical capacity limitations. If the motor has specific input and output requirements, ensure that it is operated accordingly. Respecting the feeder's limitations in terms of load capacity and operational parameters promotes longevity.

When selecting an electric rotary vibrator feeder, carefully consider the specific requirements of your application. Factors such as power supply compatibility, output capabilities, and cost should be thoroughly evaluated to ensure the chosen equipment is well-suited to meet your needs.

By following these guidelines and implementing appropriate maintenance practices, you can increase the lifespan and reliability of your electric rotary vibrator feeder, optimizing its performance in transferring products effectively.

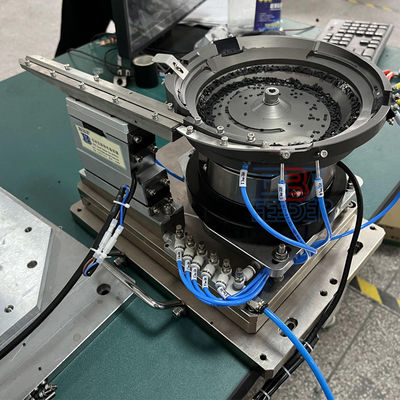

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!