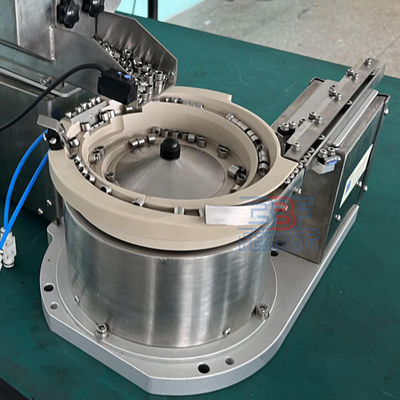

Industrial Customized Vibration Bowl Feeder Pill Screw Vibratory Bowl Feeder

1 . Descriptions:

To stay competitive, many manufacturers are turning to automation to increase productivity and efficiency. Parts feeding systems play a crucial role in automated assembly lines and have undergone significant evolution with advancing technology.

Basic parts feeding systems primarily sort and orient pieces for further processing in machines. However, advanced systems can handle multiple pieces simultaneously and employ robotic arms or other machines to precisely position the pieces.

Manufacturers face the challenge of meeting the demand for new products. To address this, they need the ability to rapidly prototype new products and swiftly reconfigure their production lines for new models. Flexible parts feeding systems are instrumental in this process as they can be easily adjusted to accommodate different types and sizes of pieces.

Miniaturization is another significant trend impacting parts feeding systems. As electronics and other components become smaller, the pieces fed into assembly machines also decrease in size. This poses a challenge for parts feeding systems as they must handle these delicate small pieces accurately without causing damage.

The optimal method for feeding parts from bulk into automated machines depends on several factors, including the type and characteristics of the parts, production volume, level of automation, and specific requirements of the automated machine.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

| Material Speciality |

Excellent Processing Properties,High Strength, High Hardness |

| Speed |

Based on Customers Requirements |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

3 . Vibratory Bowl Feeders and Their Applications:

Vibratory bowl feeders are highly versatile and widely used for feeding small to medium-sized parts. These feeders utilize vibrations to orient and feed parts from a bulk supply. The parts move along a spiral track, where they are singulated and oriented before being presented to the automated machine. Here are some common applications where vibratory bowl feeders excel:

Automated Assembly: Vibratory bowl feeders are commonly employed in automated assembly systems to deliver components such as screws, nuts, bolts, washers, and connectors to the assembly line. They ensure a consistent supply of parts in the correct orientation for assembly robots or operators.

Packaging and Sorting: Packaging and sorting operations rely on vibratory bowl feeders to align and feed items like caps, lids, small containers, and consumer products for packaging lines. These feeders help maintain a steady product flow and ensure proper orientation.

Pharmaceutical and Medical Devices: In the pharmaceutical and medical device industries, vibratory bowl feeders are used for feeding and orienting small components such as pills, capsules, vials, and medical instruments for packaging or assembly processes.

Electronics Manufacturing: Vibratory bowl feeders play a critical role in the electronics industry by feeding electronic components like resistors, capacitors, diodes, and connectors. They ensure precise placement and orientation of these components on circuit boards.

Food and Beverage: Vibratory bowl feeders are utilized in food processing and packaging for handling products such as candies, nuts, screws, and small food items. They help maintain hygiene standards and ensure consistent product presentation.

Automotive Manufacturing: Automotive assembly lines use vibratory bowl feeders to supply various small parts like screws, clips, fasteners, and connectors to the production process.

Aerospace: In aerospace manufacturing, vibratory bowl feeders are commonly used for handling and orienting components like rivets, bolts, washers, and other fasteners.

Consumer Goods: Vibratory bowl feeders are employed in the production of consumer goods such as toys, personal care products, and small appliances. They assist in feeding and orienting parts or components.

Hardware and Fasteners: In hardware manufacturing, vibratory bowl feeders are ideal for sorting and supplying screws, nuts, bolts, washers, and other fasteners in bulk.

Bearing and Bushing Assembly: Vibratory bowl feeders are commonly used in bearing and bushing manufacturing to align and feed ball bearings, roller bearings, and bushings for assembly operations.

Customized Parts Feeding: Vibratory bowl feeders can be customized to handle specific parts or components in unique manufacturing processes where other feeding methods may not be as efficient.

Part Escapements:Escapements are mechanical devices that regulate the controlled release of individual parts or components from a bulk supply. They ensure that parts are presented in a controlled and sequential manner to downstream processes or assembly stations. Part escapements prevent jams, collisions, and misalignment of parts, contributing to the efficient and precise operation of the assembly line. They are commonly used in combination with other feeding methods, such as being placed at the end of a linear track as parts exit a vibratory bowl feeder.

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!