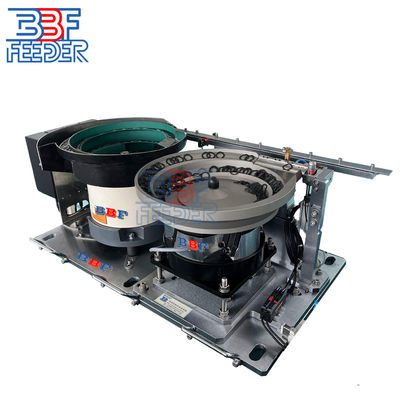

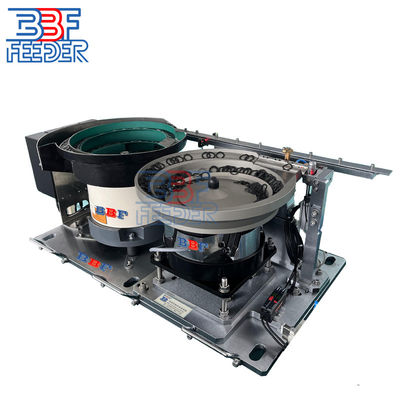

Metal Parts Vibratory Bowl Feeder Big Parts Bolt Automated Vibrating Bowl Feeder

1 . Descriptions:

To meet the evolving demands of customers, manufacturers in the processing and manufacturing industries can seamlessly integrate vibratory feeders into their applications. This integration leads to optimized production processes and provides a cost-effective alternative to manual labor. Vibratory feeders have a wide range of applications across various sectors, including consumer products, medical, pharmaceutical, automotive, electrical components, aerospace and aviation, beverage and food, and more.

A vibratory bowl feeder is a feeding system that utilizes vibration to handle small parts in bulk. It efficiently sorts and orients these parts for use in industrial production lines. By incorporating vibratory bowl feeders, workplace safety is enhanced, and there is an improvement in speed, consistency, and accuracy. These feeders are capable of handling different types of parts with varying geometries, weights, and materials, such as screws, caps, bolts, and more.

Vibratory bowl feeders are commonly used alongside other production equipment, particularly automated filling or packaging machines. When integrated with pick-and-place robots, grippers, camera systems, PLC systems, and other hardware, they further optimize efficiency and significantly reduce production time.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Material Speciality |

Excellent Processing Properties,High Strength, High Hardness |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/800W/1000W/1500W/2000W/3000W |

| Color |

Green or Based on Customers' Requirement |

| Speed |

Based on Customers Requirements |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 working weeks |

3 . Application:

Using a vibratory bowl feeder offers numerous benefits, leading to time and cost savings in the production line. The feeder seamlessly integrates with filling machines and other production equipment, ensuring precise and efficient container filling.

Operating in an automated manner, the feeder controls the flow of ingredients, halting when the container reaches its desired level or a predetermined limit. This prevents overfilling and enables accurate ingredient measurement.

Vibratory bowl feeders contribute to streamlined operations, optimizing production processes and minimizing waste. They are easy to clean and can accommodate various ingredient types. Moreover, their modular and customizable design allows for convenient modifications and expansions of the production line.

The functionality of vibratory feeders involves agitating the ingredients or components within the bowl, utilizing movements such as back-and-forth, up-and-down, and circular rotations. This agitation effectively directs the ingredients into the container or redirects them to another machine in the production line, such as passing screws to a machine for fitting them into a door lock.

However, it's important to note that vibratory bowl feeders are not suitable for thorough mixing of food ingredients. For proper mixing, a paddle feeder or another appropriate device should be used. Selecting the right equipment for specific tasks is crucial to achieve accurate and consistent results.

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!