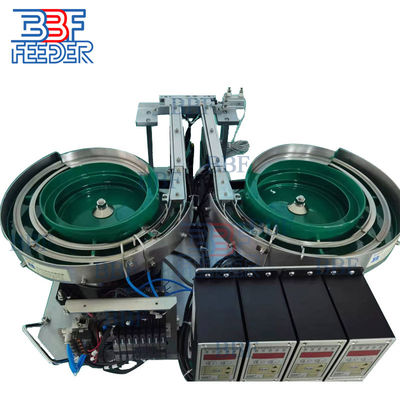

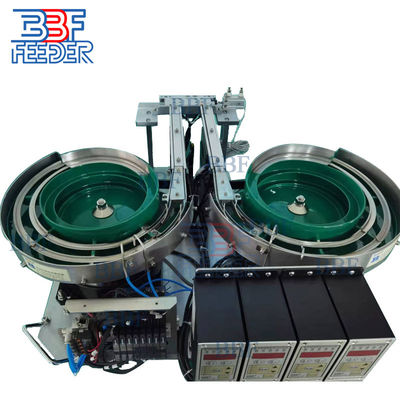

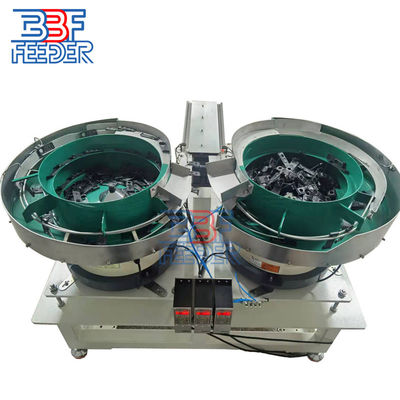

Double Vibratory Bowl Feeder Screw Caps Customized Vibrating Bowl Feeder

1 . Descriptions:

Vibratory bowl feeders, widely used in industrial production environments, are a type of versatile machinery or equipment for parts-feeding systems on assembly lines. These self-contained mechanical devices have been in use since the mid-20th century, offering resilience and efficiency.

The main principle behind vibratory bowl feeders is the utilization of vibration to align and feed small parts in production lines. Electromagnets are employed to generate vibrations, which are then converted into mechanical vibrations. These mechanical vibrations are harnessed and transferred to the conveying track on the bowl, propelling the components along the track and feeding them into the production line.

To achieve the electromagnetic actuation, a magnetic coil is positioned beneath the bowl, which is mounted on springs to restrict vertical movement. An external power source magnetizes the coil, creating vibrations that actuate the bowl. Typically, 1 to 6 electromagnets are placed under the feeder base. Once the electromagnetic vibrations are converted into mechanical vibrations, the components in the bowl feeder are propelled onto the bowl conveying tracks for further production.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Material Speciality |

Excellent Processing Properties,High Strength, High Hardness |

| Voltage |

AC220V/110V 60Hz |

| Power |

300W/500W/800W/1000W/1500W/2000W/3000W |

| Package |

Wooden Case Package |

| Bowl Finishing |

Polishing or PU Coating |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 working weeks |

3 . How They Work:

Vibratory bowl feeders are widely used in various industrial sectors that require flexible feeding systems for high-volume production of parts or pieces. They find applications in industries such as pharmaceuticals, consumer electronics, electrical parts, plastics, cosmetics, food, fashion, automotive, and more.

One notable application of vibratory bowl feeders is in vial and tube capping machines. These automated systems are designed to handle small polypropylene screw-on caps for microcentrifuge tubes and vials. The caps and vials are fed from vibratory bowls, with a feeding rate of approximately 80 parts per minute. The system can be easily adjusted to accommodate similar products.

Another application of bowl feeders is in pill bottling systems. Large batches of pills or capsules are dispensed into the vibratory bowl feeder for counting and bottling. The vibratory feeder's vibration ensures that the pills continue moving toward the exit and into the bottle, one by one, without congestion.

Vibratory bowl feeders provide industries with a cost-effective automated production system that increases efficiency while reducing production costs. They offer a reliable and efficient solution for parts feeding in various manufacturing processes.

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!