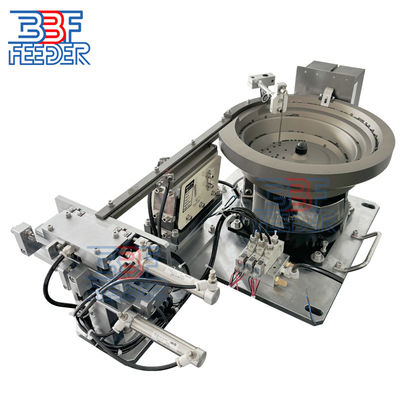

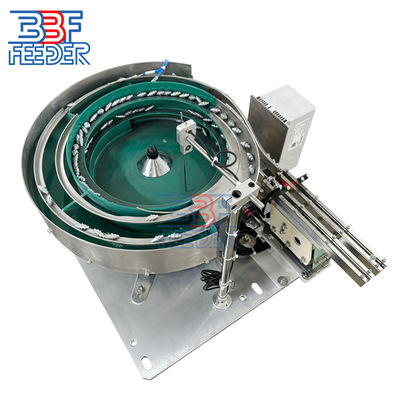

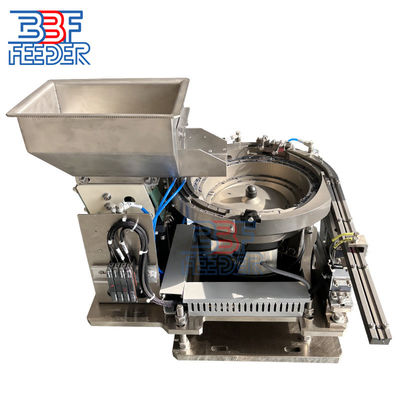

Industrial Vibratory Bowl Feeder Customized Components Parts Automation Feeding

1 . Descriptions:

There are several steps that need to be taken in order to ensure that a vibratory bowl feeder is produced that meets the customer's requirements:

Evaluate your needs: We need to understand the size and shape of your product, as well as your requirements for the state of the material to be transferred.

Mail the required material: After the engineer confirms that the vibratory bowl feeder can be produced according to the customer's requirements, the customer needs to mail the material in order to design and test the vibratory bowl feeder.

Design and Confirmation: After receiving the material, the engineer will design the drawing of the vibratory bowl feeder according to the characteristics of the material, and can arrange the production after the customer confirms.

Production and testing: After the production is completed, we will test the vibratory bowl feeder continuously for 4 hours to observe whether there will be any problems such as material jamming.

Delivery and after-sales service: After confirming that the vibratory bowl feeder can operate normally and continuously, we will deliver the vibratory bowl feeder to the customer's designated location, and we will provide solutions even if there are any problems in the process of using the vibratory bowl feeder. We provide a two-year warranty.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

Color

|

Green or Based on Customers' Requirement |

| After-sales Service |

Spare Parts and Technology Support |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

3 . Application of Vibratory Bowl Feeders :

In manufacturing, vibratory bowl feeders are used in a wide variety of applications, including vibratory bowl feeders that are often used to convey hinges.

A major U.S. appliance manufacturer needed vibratory bowl feeders to convey hinges to install microwave and oven doors. Different vibratory bowl feeders are designed according to the size and shape of the hinges to ensure that the hinges do not jam or tilt in transit, and under the detection of integrated photoelectric sensors, qualified hinges are accurately conveyed to the designated location, where they are grabbed by a robotic arm and installed.

Utilizing the vibratory bowl feeder to convey hinges plays a driving role in automated production, improving production efficiency and product quality. If your production line needs automated production equipment, welcome to contact us.

4 . More Pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!